One-Stop Precision Aluminum Solutions

industry applications

Engineered for Precision, Built for Versatility

Huizhou Kecheng Precision Aluminum Co., Ltd. leverages state-of-the-art equipment, advanced processing techniques, and a skilled technical team to deliver aluminum products that are renowned for their high precision, superior quality, excellent surface finish, outstanding durability, and flexible customization options. Backed by a rigorous quality control system, we ensure that every product meets the highest standards of performance and reliability.

Why Trust Us

Inspired by our vision and guided by our values

Huizhou Kecheng Precision Aluminum Co., Ltd. was established in March 2019 and operates a modern facility covering 20,000 square meters with a workforce of 243 employees. As a national high-tech enterprise, we integrate R&D, production, and sales to deliver comprehensive solutions to clients worldwide.

Proven Expertise

Reliable Infrastructure

Quality Without Compromise

Manufactured through Kecheng

Case Studies

Put your parts

into production today

All information and uploads are secure and confidential.

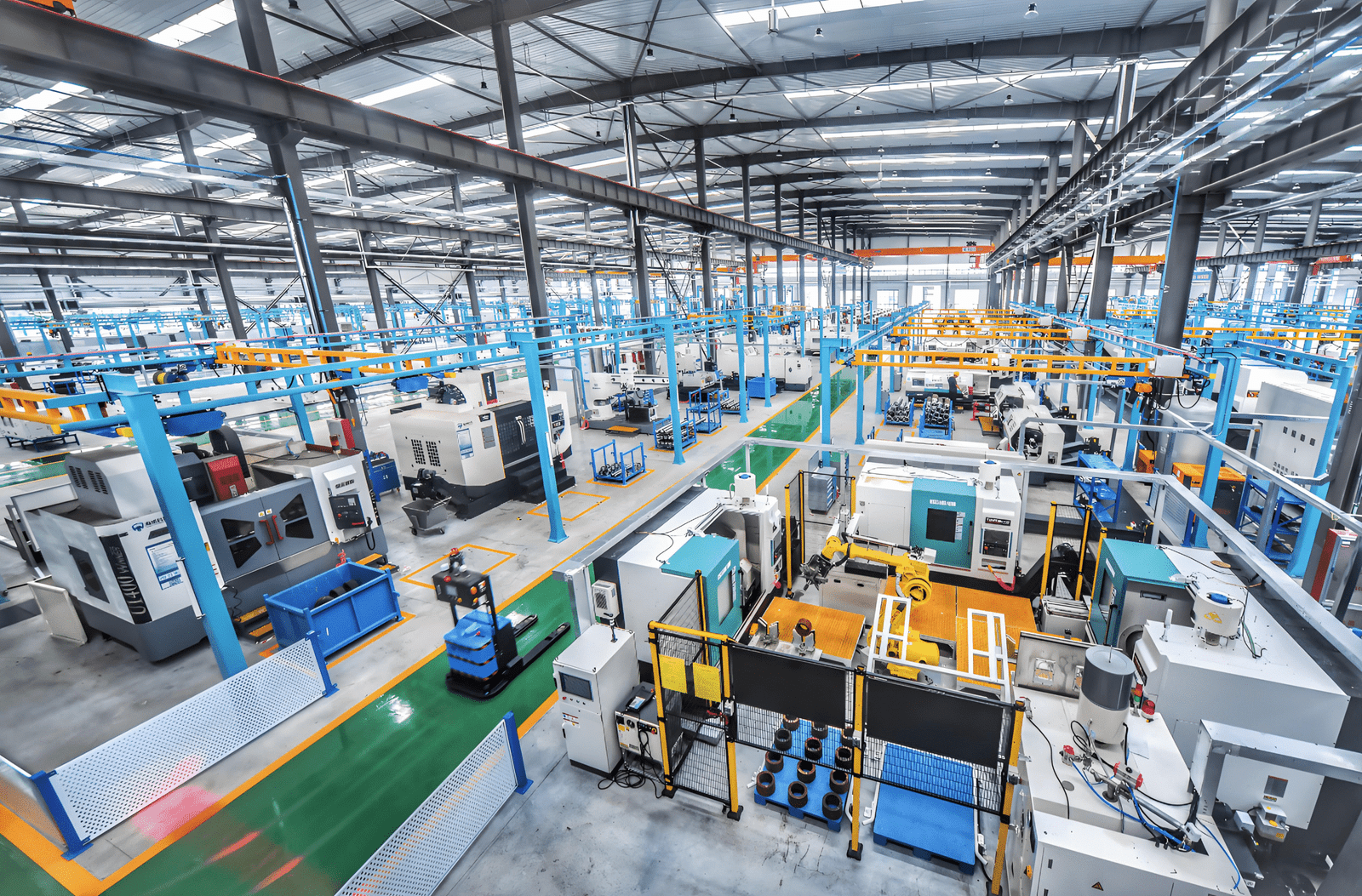

State-of-the-Art Infrastructure: Leading Industrial Innovation

Manufacturing Capabilities

CNC Machining Center

- 25 precision CNC machines including 4 automated 5-axis systems and 2 4-axis systems

- 5-axis CNC machines deliver simultaneous multi-plane machining capability, enabling single-setup completion of intricate geometries, greatly improving production efficiency and processing accuracy, reducing human errors, and achieving perfect refinement of product details.

• 4-axis CNC machines demonstrate high efficiency and stability in the processing of specific types of products. The two complement each other and comprehensively cover the processing demands of various aluminum products

7 extrusion presses with diversified tonnages

• 700T (x4) • 600T (x1) • 800T (x1) • 1450T (x1)

• These high-performance extrusion presses deliver tight process control, ensuring high-precision and ultra-stable mechanical properties in aluminum profiles, laying a zero-defect foundation for downstream CNC/assembly operations. Engineered for lean manufacturing, our presses efficiently meet the demands of diverse and large-scale production orders.

Committed to upholding the highest standards of quality and efficiency

Expert Workforce

End-to-End Solutions: Seamless Integration Across the Value Chain

From Design to Finish, Huizhou Kecheng Precision Aluminum Industry provides One-Stop Solutions. During the extrusion die design phase, we utilize CAD/CAM technology to create high-precision, durable molds that ensure optimal aluminum profile forming quality. Post-CNC machining, our specialized surface treatment team employs processes including anodizing, brushing, sandblasting, and powder coating to enhance both aesthetics and functionality—improving corrosion resistance, wear resistance, and meeting diverse client requirements. This vertically integrated approach delivers raw material to finished product solutions, saving time/costs while ensuring efficient service.

CNC Engineering Team

CNC Operations Team

R&D Division

Unlocking Boundless Possibilities